For many hobbyists hand planes are a strangely logical solution. My decision was not a fulfillment of a secret desire to live centuries ago. Using hand planes for flattening a single side before running it through my planer was based only in practicality. I imagine hand planes are practical in most shops, but to varying degrees.

My transition to molding planes occurred in a similar cry for 'mercy.' I was looking through Amana's web page trying to find something specific and ended up dropping $85 on a compromise.

I never get asked Chris' question. I often feel like I am the last step. Like a try and a fore plane, however, hollows and rounds are relevant and a strangely logical solution to many hobbyists journey and craft. The solution they offer--flexibility--is practical; the means by which they offer it--putting your hand to your work--is wonderful.

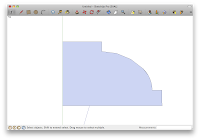

A few weeks ago I posted a couple entries detailing several things that can be done with only a #6 hollow or a #6 round. Let us take a quick look at what can be done with a single pair in combination.

Ogee (60 degree circle segments at 30 degrees) with Fillet

=

Ogee (60 degree circle segments at 60 degrees) with Fillet

=

Ogee (90 degree circle segments) with fillet

=

(disregard the quirk)

Reverse Ogee

=

Ovolo and Cove

=

90 degree Cove and Ovolo

=

(60 degree ovularish) Cove and (90 degree) Ovolo

=

Or would you like the oval the other way?

etc., etc., ETC!...

That's 27 different profiles illustrated that can be created with one hollow and/or one round.

We've looked at making rabbets

We've looked at steering planes with rabbets

We've looked at using rabbets as depth gauges.

We've looked at laying these shapes out before.

Stay tuned. We'll take a look at what can be done with two pairs. You'll see why I always recommend starting with more pairs than one: we can probably come up with 100 profiles with just 2 pairs.

We'll also execute the supporting molding and top edge of the John Townsend chest in the Metropolitan Museum of Arts with no new tooling, no real compromises and a few work-arounds.

Clearly, it's pretty difficult to keep up with a router.