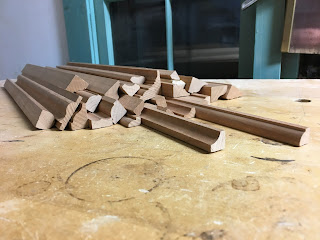

MERCY!!! I was trying to talk about side rounds here, but...

Throughout the many years I’ve been making/selling planes I have seen

several common requests go in and out of fashion. Some months I get numerous requests

for moving fillesters. On other occasions my time is spent responding to the

wave of those that suddenly want tongue and grooves, 3/8” side beads, panel

raisers, skewed rabbets, etc.

These past few weeks I have been responding to a

significant number of people interested in a pair of Rule Joint Planes. The

number has been so significant, in fact, that I am here, writing this blog, in comprehensive

response. (I will, of course, add it to my

FAQ page, too.)

For those of you that happen to stumble upon this blog post

and do not know what a rule joint is, that’s ok. You may, after all, only know it

as the integral joint of a drop leaf table. You may even have a few in your living room. Your grandmother’s

favorite piece of furniture may have showcased it, like that of my own...

The joint allows a table to be extended easily while decorating the seam with a common moulding profile: a square ovolo with fillets.

A rule joint is comprised of two sides. The primary side is the top, which is a square ovolo with fillet that is ideally more than 90 degrees of a circle.

The second half is a square cove, ideally with a slight flat at the bottom.

All of this allows the joint to be opened and closed seamlessly, without seeing any voids.

At first glance you may conclude that these profiles are easily executed with simple dedicated planes because they are simple, specific profiles. To some degree you are correct, each portion could be made with these planes.

The issue with this process is getting the two profiles to align perfectly because the depth stops of common dedicated planes will register upon different faces of the table's top.

This is fine if the thickness of the pieces being worked is exactly the width for which the planes were designed: no more, no less.

This fact is, however, an issue once any slight change in stock is worked.

The slight change will result in a joint that does not align.

The profiles above do not match. In fact, any material that isn't exactly thicknessed for the planes' design will not match. Thus, common, sprung, dedicated planes will not work for this joint.

"But Matt," you say, "there are historical examples of rule joint planes. Why not this?"

Let us take a closer look at rule joint planes while acknowledging the one truth I've illustrated above: the two planes must register upon the same face.

The fences of the dedicated rule joint planes must register upon the underside...

(in the scenario above the plane on the left has no depth stop, which is a MAJOR issue)

or the top

This final illustration would be my choice, but there are still more issues involved. Due to the need for the planes to register upon the top of the piece, both planes cannot be sprung. This means that the scraping action of the cutting edge is greatly increased. This greatly reduces the edge's longevity. See

here and

here for further information on this subject because there are even more issues regarding seasonal maintenance and difficulty sharpening (not just increased amount of sharpening.)

I guess what I'm saying is the following:

Rule joints and rule joint planes are perfect examples of where hollows and rounds excel. I wrote a blog post on the actual steps years ago. It can be found

here.

A rule joint is a perfect place to begin for somebody interested in introducing hollows and rounds into their work. The two portions of this joint are elementary and may be perfected in two or three attempts. In fact, I teach classes on using these planes and the two profiles included in the rule joint are only the third and fourth in a weekend spent using profiled planes excessively.

Be done with the joint before lunch:

If you're running ahead of the group then do it better:

Make a rule joint with hollows and rounds knowing the whole time that these two profiles are only a portion of what may be done with a single pair.

In short, I don't make rule joint planes because I don't want my name on the nonfunctioning tools in your workshop. Make the joint with hollows and rounds and then use the same tools to do much more.