A dedicated moulding plane makes a single moulding profile. These planes will make one profile at one angle, one location, and one orientation. Dedicated planes will have a fence and a depth stop. These two features make the plane apparently simple to use. The fence and depth stop also limit the plane by mandating the need of reference surfaces for each.

Hollows and rounds are versatile because they lack fences and depth stops. Hollows and rounds are attractive to woodworkers because they offer something which machinery can not: the idea of infinity. This idea of infinite possibilities is achievable due to the lack of an integral fence and depth stop.

The benefits in using a rabbet plane are similar to those of hollows and rounds: the lack of a fence and depth stop is advantageous because the lack of these two features means that there is no reliance upon either.

When making a single rabbet upon a corner of a board with a moving fillister or any fenced plane, both fence and depth stops may have predictable surfaces upon which to register...

or they may not. Depending upon dimensions, the face and the edge are not always accessible.

In these cases will you let the fence register against your sticking board? There may not be a better option.

When making two rabbets, as you will with most minimal moulding profiles, the reference surfaces for the fence and depth stop can become less clear and predictable: face and edge or face and previous rabbet? Just hope the rabbet doesn't change dimension throughout the length because your stops depend upon uniformity.

Making three rabbets generally confiscates at least one of those reference surfaces from the plane.

What happens when you need to make ten rabbets next to each other for a slightly complicated moulding and you rely upon a fence or depth stop?

Or, what if your fence does not extend wide enough or your depth stop not adequately deep?

These last example aren't good examples because you should be working on an angled surface here. So what do you do when working on an angled surface with a fenced plane?

I don't know what to do in these instances because I don't face such problems. I use a rabbet plane.

Mouldings, however? Get a proper rabbet plane now or a rabbet plane after being discouraged by other options. Either way, you're getting a rabbet plane.

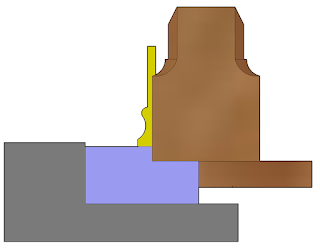

(I've illustrated a moving fillister making rabbets above, any fenced plane will face similar problems once producing inside of the absolute edge.)

These last example aren't good examples because you should be working on an angled surface here. So what do you do when working on an angled surface with a fenced plane?

I don't know what to do in these instances because I don't face such problems. I use a rabbet plane.

A rabbet plane is highly versatile tool that relies only upon the user. If you fight the plane to make accurate rabbets then you have a rabbet plane that is not accurately tuned and ought to be fought. Your issue is with the tool that you have and is not with the tool in principle.

There are, of course, many methods for making rabbets by hand. A block rabbet plane, jack rabbet plane, bench rabbet plane, shoulder plane, Stanley rebate plane, moving fillester plane, Combination plane and etc., etc., etc., can all be successfully used to execute our subject. If in use, however, you ever find yourself thinking "This is a tedious method to produce one rabbet" or "this is insane, there ought be a better way" then your conclusion shall be that it's tediously insane with the tools you've been sold. The conclusion shall not be that it is tedious to produce by hand. You simply have the wrong tool.

In short, if you're looking to add a single relief for drawer faces or window sash then, sure, go with any one of a number of fenced planes. Uniformity is ideal in these situations and your husband will be impressed with your gadgetry. Other than a rabbet plane,I can not recommend one option specifically for any task warranting this uniformity because I'd use a table saw 10 out of 10 times on these occasions.

(I've illustrated a moving fillister making rabbets above, any fenced plane will face similar problems once producing inside of the absolute edge.)

Note: Do you want to win a free 3/16" side bead plane? I am trying to gauge how many people actually read these posts. Please send one email to matt@msbickford.com with the subject "Raffle" to be eligible. The raffle ends at midnight on 12/8, EST. The winner will be picked at random on Saturday, 12/9.

I ask that you please keep this raffle quiet. Telling other people about this contest will reduce the chances of you winning and me sending the tool to somebody that actually wants it. I'm not trying to increase my readership here, just rewarding one of those that does. PLEASE DO NOT PUBLISH THIS! PLEASE DO NOT ENTER MULTIPLE TIMES USING VARIOUS email addresses.

If I see reference to this raffle on the internet then I reserve the right to disqualify the person who posted it. Again, I'm not interested in increasing my numbers of followers with this so please do not use it to increase your 'likes'. I'm only interested in rewarding one of the readers who have made it this far.

The one winner will receive an x-out 3/16" side bead plane delivered anywhere that the USPS will take it . The plane will be shipped as "used", but any international winner will be responsible for their assumed taxes. (The plane is of the same standard as any other plane I sell, I just don't like the look of the wood.)

If I see reference to this raffle on the internet then I reserve the right to disqualify the person who posted it. Again, I'm not interested in increasing my numbers of followers with this so please do not use it to increase your 'likes'. I'm only interested in rewarding one of the readers who have made it this far.

The one winner will receive an x-out 3/16" side bead plane delivered anywhere that the USPS will take it . The plane will be shipped as "used", but any international winner will be responsible for their assumed taxes. (The plane is of the same standard as any other plane I sell, I just don't like the look of the wood.)

Finally, I will not be searching the surface of this wonderful world to contact the winner. I will allude to the winner's handle in the comment section and on Instagram when the raffle is expired. An email will be sent. It's up to you to respond to me.

Seriously, let's just have fun among those of us that are seemingly interested in moving fillisters to varying degrees. Please don't tell anybody about it.

The old books that I've read, esp. Modern Practical Joinery by Ellis advocate cutting a number of grooves with a plough and then using a chisel and mallet to chop out large chunks of waste and bringing to size with a rebate plane. Having used this method several times its quick and would even work on the beveled stock you use for your last illustration, as long as you used a narrow iron.

ReplyDeleteA fillister can be used as long as you don't want a sticking board in the way and you start with the rebates furthest away from the edge, but it is often limited by the depth achievable from the depth stop.

I like the new posts, which contain some real nuggets of information, so thanks for writing. Regarding the free 3/16" side bead, a generous offer but as I've already got one (not one of yours, something a hundred years old) I'll leave it to someone else.

Cheers, david